The premium packaging market has been experiencing a significant trend of growth worldwide. Premium packaging refers to high-quality, aesthetically-pleasing, and durable packaging solutions that are used for luxury goods, high-end products, and exclusive consumer experiences. As

the demand for premium packaging continues to rise, the development and innovation of rigid box machines, case makers, and related machines have played a crucial role in meeting this demand efficiently.

Rigid box machines, also known as box making machines, are used for the efficient production of rigid boxes. These machines automate the process of cutting, folding, and gluing cardboard or paperboard to create sturdy and visually appealing boxes. They offer high precision, speed,

and versatility, allowing manufacturers to produce a wide range of box styles and sizes to cater to different product requirements.

Case makers are another essential machine used in the packaging industry. These machines are designed to manufacture custom-designed cases or rigid boxes suitable for specific products. Case makers work by cutting and creasing a flat sheet of cardboard or paperboard, which is

then folded and glued to create a rigid box or case. They enable manufacturers to produce bespoke packaging solutions tailored to their client's branding, product specifications, and aesthetic preferences.

The development and innovation of rigid box machines, case makers, and related machines have brought several advancements to the packaging industry. These advancements include:

1. Rapid production: Modern rigid box machines and case makers are equipped with advanced automation features, enabling faster production rates while maintaining high-quality standards. This helps meet the growing demand for premium packaging in a timely manner.

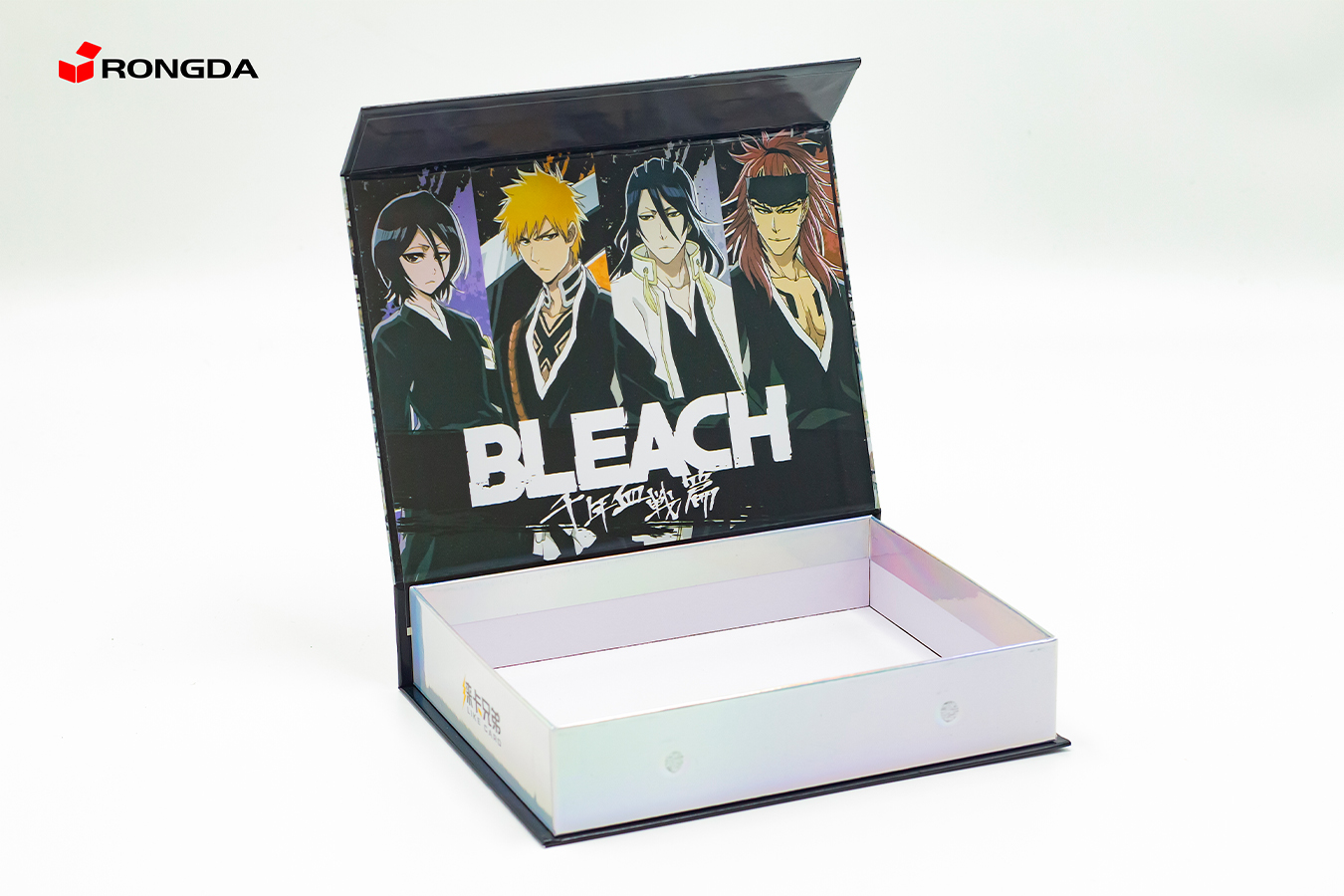

2. Customization capabilities: The latest machines offer greater flexibility in terms of box size, shape, and design. They can easily accommodate various box styles, such as flip-top boxes, book-style boxes, drawer boxes, and more, allowing manufacturers to create customized packaging

solutions that align with brand identity and product aesthetics.

3. Enhanced precision and quality control: Innovations in rigid box machines and case makers have resulted in improved cutting, folding, and gluing techniques. This ensures precise box dimensions, consistent adhesive application, and overall high-quality production, which is essential

for premium packaging.

4. Cost-effectiveness and efficiency: Advanced machines optimize material usage, reduce production waste, and increase overall operational efficiency, resulting in cost savings for manufacturers. Additionally, their ability to streamline the packaging process reduces labor requirements,

thus improving productivity.

5. Integration with digital technologies: Manufacturers are increasingly integrating rigid box machines, case makers, and related machines with digital technologies such as computer-aided design (CAD) software, digital printing, and coding systems. These integrations enhance workflow

automation, offer real-time quality control monitoring, and enable customization based on digital designs.

Overall, the development and innovation of rigid box machines, case makers, and related machines have revolutionized the premium packaging market. These machines provide manufacturers with the ability to meet the increasing demand for high-quality packaging, offer customization options, improve production efficiency, and ultimately deliver an enhanced consumer experience.

Rongda, as a professional supplier of premium packaging equipment, can provide you with a full range of consulting services to create the most suitable production line for your needs! Rongda can offer high-end premium packaging production line customization, according to site,

output, product design and budget, to provide customers with manual / semi-automatic / fully automatic whole line solutions, involving gift boxes, electronic product packaging boxes, luxury packaging boxes, cosmetic packaging boxes, wine boxes, candy/chocolate packaging boxes,

cigarette boxes, etc. all conventional or unconventional premium box packaging of Rigid boxes/book type boxes/collapsible boxes/tall boxes etc. Welcome your consultation and inquiry!